Choosing the Best Industrial Mixer Grinder

Productivity and efficiency in businesses form the basis of their success in today’s fast-speed industries. The industrial mixer grinder is one of the crucial machines in the food processing, pharmaceutical, and chemical sectors. It makes uniform blending, grinding, and emulsion of several ingredients in producing quality goods.

This is an article detailing industrial mixer grinders, their varieties, and applications, as well as their benefits compared to possible purchasing considerations. It is meant for an entrepreneur or a factory manager looking to expand the business or find a more efficient grinding solution.

Types of Industrial Mixer Grinders

Industrial mixer grinders have different types of mixers designed to suit industry requirements. A few common ones are:

1. Batch Mixers

- This is for blending and grinding ingredients in specific quantities.

- It is good for applications requiring control over ingredient ratios.

2. Continuous Mixers

- Meant for the continuous process type of production line.

- For massive food processing industries and pharmaceutical production lines.

3. Ribbon Blenders

- They are equipped with a helical ribbon blade to blend dry powders and granules.

- The above mixers find applications in the food, chemical, and pharmaceutical industries.

4. High-Speed Grinder Mixers

- They are often used for grinding and emulsification of particles.

- Meat processing, dairy industries, and spice grinding are common applications.

5. Planetary Mixers

- It has the features of a rotating blade or bowl for thorough mixing.

- Used widely in the bakeries and confectionery industries.

Applications of Industrial Mixer Grinders

Industrial mixer grinders are used widely across all types of industries for their versatility and efficiency. Here are some of their applications:

1. Food Processing Industry

- These are used to grind spices, meat, vegetables, and dairy products.

- These are helpful in the production of sauces, pastes, and processed foods.

2. Pharmaceutical Industry

- They are required to mix medicinal powders and granules.

- These are used to prepare syrups, ointments, and capsules.

3. Chemical Industry

- They are used to mix chemicals and powders for industrial purposes.

- Used in the formulation of coatings, paints, and adhesives.

4. Cosmetic Industry

- Used in emulsifying creams, lotions, and gels.

- Gives cosmetic products a uniform texture and consistency.

Featured Products by Lords Xtra

Lords Xtra encompasses all types of high-performance industrial mixer grinders. Among them include:

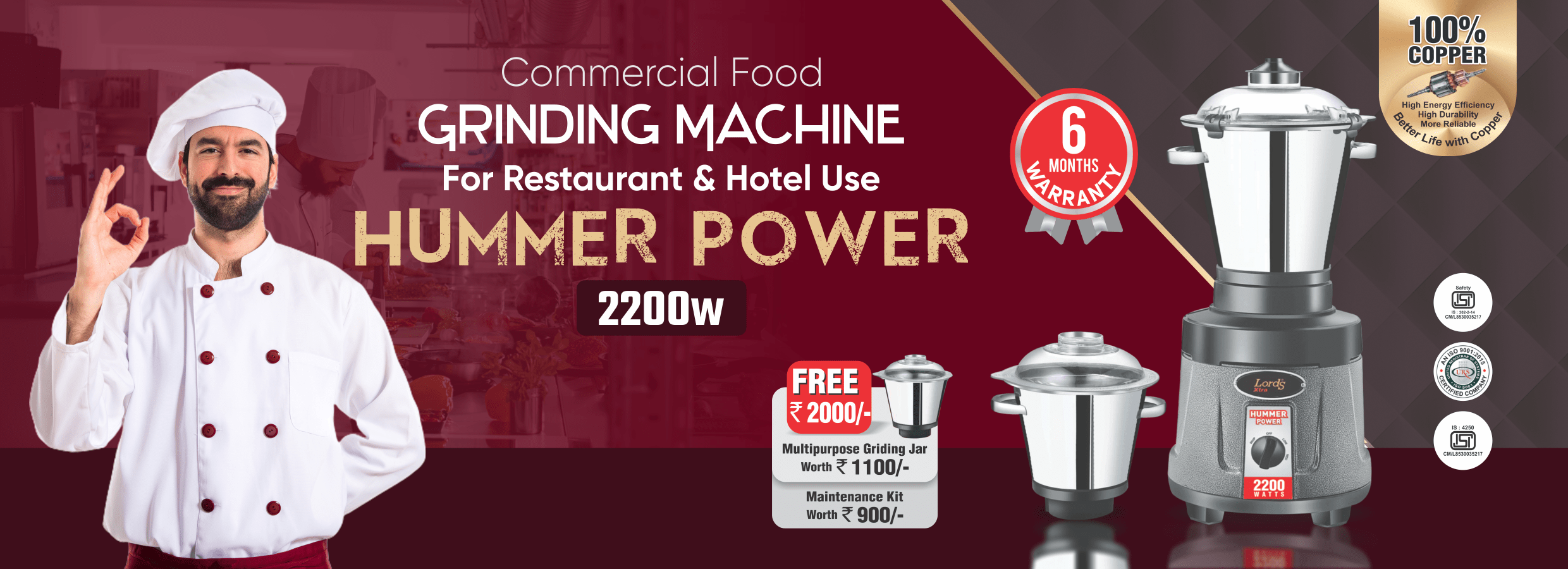

- Hummer Power 2200 watts – A heavy-duty mixing and grinding machine like Hummer Power 2200 watts can handle tough ingredients most efficiently. A highly powered motor with stainless steel blades ensures steady and undisturbed grinding and mixing for the food and beverage industries, which require a continuous grinding process without overheating.

- Hummer Power 2060 watts – This version strikes a perfect balance between power and efficiency. Hummer Power 2060 watts is good for industrial processing that operates in the range of medium to large scale. It works well for food processing units and related spice-grinding industries. Equipped with advanced safety features and overload protection, it guarantees smooth operating action.

- Hummer Power 1760 watts – Hummer Power 1760 watts is a compact package with extreme efficiency, mainly used in small to medium-scale industries. It is better in grinding and has a precision-crafted motor. It is ideal for applications requiring accuracy and uniformity.

These machines are made with durability and efficiency in the core product, with the desire to sell only the best, most efficient options to industrial businesses seeking reliable grinding solutions.

Benefits of Using an Industrial Mixer Grinder

Industrial mixer grinder investment provides several benefits, including:

1. Higher Productivity

- It saves labour time and accelerates the production process.

- It can handle a large amount of ingredients.

2. Quality Output

- It provides uniform blending and grinding, resulting in quality products.

- It reduces the number of defects and variations in the final product.

3. Economical Operations

- It reduces raw material wastage.

- It saves on the use of multiple machines since it can perform multiple functions in one unit.

4. Hygienic and Safe

- Most industrial mixers are made of stainless steel, which ensures hygiene and easy cleaning.

- Equipped with safety features such as overload protection and automatic shut-off.

5. Versatile Functionality

- Suitable for wet and dry grinding.

- It can handle multiple types of ingredients, from soft pastes to hard granules.

Factors to Consider Before Buying an Industrial Mixer Grinder

The choice of machine will depend on several factors. Here are some of the most important considerations:

1. Capacity and Size

- Volume of ingredients in one batch.

- Choose a machine according to your production scale.

2. Material and Build Quality

- Stainless steel for durability and hygiene.

- Industry safety and sanitation.

3. Power and Speed

- Consider the motor power (measured in HP) and RPM (rotations per minute).

- The toughest and most dense ingredients would require a high-power motor.

4. Ease of Maintenance

- Look for the machines in terms of easy parts cleaning and with little time being wasted on downtime.

- The availability of spare parts and customer support is essential.

5. Automation and Controls

- Advanced models come with programmable settings and high-precision performance.

- Digital Controls and safety features enhance usability.

Maintenance and Care Tips for Industrial Mixer Grinders

A properly maintained industrial mixer grinder will serve for a longer period and in an efficient manner. Here are the most crucial tips:

1. Cleaning after Each Use

- Clean all the parts after use to avoid contamination.

- Use food-grade cleaning solutions to maintain hygiene.

2. Lubrication of Moving Parts

- Use food-grade lubricants to avoid wear and tear.

- Check for loose bolts and tighten them if required.

3. Periodic Inspection

- Schedule regular checks for the efficiency of the motor and the sharpness of the blades.

- Replace worn-out parts to avoid sudden breakdowns.

4. Storage

- Store in dry and clean environments to avoid rust and corrosion.

- Cover the machine when not in use to prevent dust accumulation.

Conclusion

The industrial mixer grinder is one of the most prominent items for businesses in large-scale food processing, pharmaceuticals, and chemical processing. Its key benefit lies in productivity enhancement through consistency and cost-effectiveness. While selecting a mixer grinder, think about capacity, material quality, power, and ease of maintenance when making the best investment.

High-quality industrial mixer grinders, Hummer Power 2200 watts, Hummer Power 2060 watts, and Hummer Power 1760 watts for efficiency and durability. Choose among these for the right grinder in your business operations.